How does the Federal Flexible Coupling™ work?

A Federal Flexible Coupling should be used between the propeller shaft and the engine of your boat to absorb the misalignment caused by structural distortion of the hull in a seaway. Changes in the hull from water absorption and shifting of ballast also tend to cause misalignment between the propeller and motor. Even a small degree of misalignment with rigid couplings will cause shaft whip, excessive vibration, and impose extreme stress on the reverse gear and stuffing box. It is particularly important that flexible couplings be properly used with any motor that has rubber engine mountings to allow the engine to float freely and to prevent distortion of the shaft. Propeller vibration is substantially dampened by the use of the Federal Flexible Coupling. There is no metal to metal contact. This helps to reduce electrolysis by isolating the iron parts of the engine from the bronze shafting and propeller. Grounding straps are available for boats with bonded electrolytic systems.

The Federal Flexible Coupling consists of a metal hub and flange. The metal hub is accurately bored to receive the propeller shaft, and the face of the flange is machined to match the engine coupling. The neoprene rubber bushings have a bonded inner brass sleeve and the entire bushing is pressed into the flange at the proper compression. Alloy steel spider pins screw through the bushing into the hub and are locked into position. The rubber bushings are sufficient to absorb propeller vibration and to allow slight angular misalignment. In replacing the propeller half of the engine coupling, the Federal Coupling requires but a fraction of an inch additional space for installation. The Flexible Coupling is not designed to do the work of a universal joint. The engine should be aligned properly before installation in order that the flexibility of the coupling may be used entirely to compensate for misalignments caused by hull distortion and motor movement.

The Federal coupling may be readily installed at any time; no alternations are necessary to either the engine or the propeller shaft. Align the engine, using the existing rigid couplings, then remove the rigid coupling from the propeller shaft and put the Federal Flexible Coupling on in its place. There need be no change in the position of the propeller.

The Federal Flexible Coupling will absorb both thrust and torsional loads. The pins and rubber bushings are replaceable in case of damage. Couplings with standard bore and keyways are available for most gasoline engines with ratings not exceeding 500 horsepower, diesel engines to 900 foot pounds torque. All necessary bolts, nuts, and set screws are furnished. Professional installation is highly encouraged.

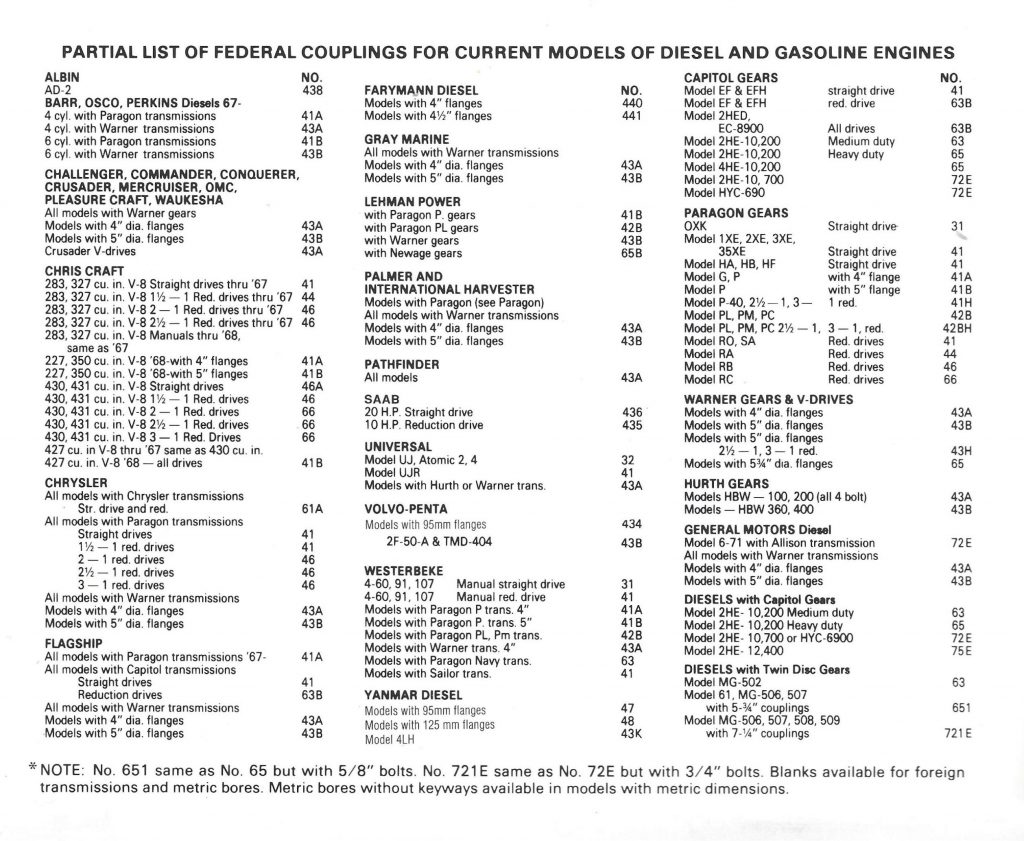

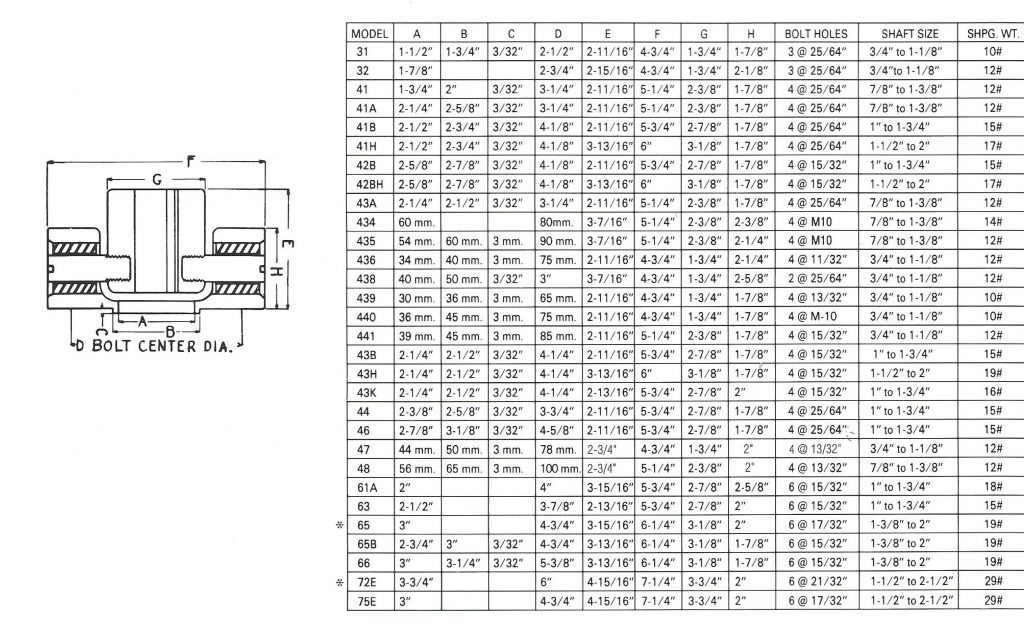

Dimensions

Models